Temperature and humidity play an important role in deciding the quality of Print. As these factors change under operation, they primarily influence the ink's characteristics and the substrate's properties.

Let’s Know. How?

EFFECT OF INCREASED TEMPERATURE ON PRINT QUALITY-

Modern flexographic printing presses typically operate at a very high speed. Due to this, the press generates more heat per time unit, which results in a higher working temperature of the printing units of the press. As a result, it is important to know how inks perform at a temperature above room temperature, as properties such as viscosity and surface energy change at higher temperatures.

This investigation aims to study the effect of temperature on ink performance and print quality in a printing press. The viscosity and temperature curves of different inks are measured as part of the investigation. As per the measurements, viscosity decreases with shear rate and temperature.

The ink was heated to simulate real conditions and evaluate the impact of elevation in temperature on print quality using a Roll-to-Roll Printing Press. It showed that print density was directly proportional to the temperature due to lower ink viscosity.

EFFECT OF ELEVATED TEMPERATURES ON VISCOSITY OF THE INK

Mottling at a shorter wavelength is reduced at high temperatures. As the wavelength increases, it remains unchanged or heightened since the ink is immobilised before variations are evened out. Nevertheless, the degree of mottling at a long wavelength is minimal.

At higher temperatures, dot gain somewhat reduces due to the faster immobilisation of the ink. As a result of an excessively high working temperature, the solvent in ink evaporates more quickly, which increases its viscosity.

Consequently, the ability of the ink to flow will be compromised, which would result in decreased transferability of ink between anilox and plate and between the plate and substrate.

Inks with high viscosity are more likely to block the plate, particularly in plate areas with a finer screen. At high temperatures, the viscosity of the ink should be measured at all times, and solvent must be added at necessary intervals when the viscosity increases.

EFFECT OF LOW TEMPERATURES ON THE INK

Even low working temperatures are not ideal because it decreases the solubility of the ink and leads to its hardening. As a result, the transferability of the ink will reduce. To avoid that, the ink has to be stirred constantly while heating it to prevent the temperature from decreasing.

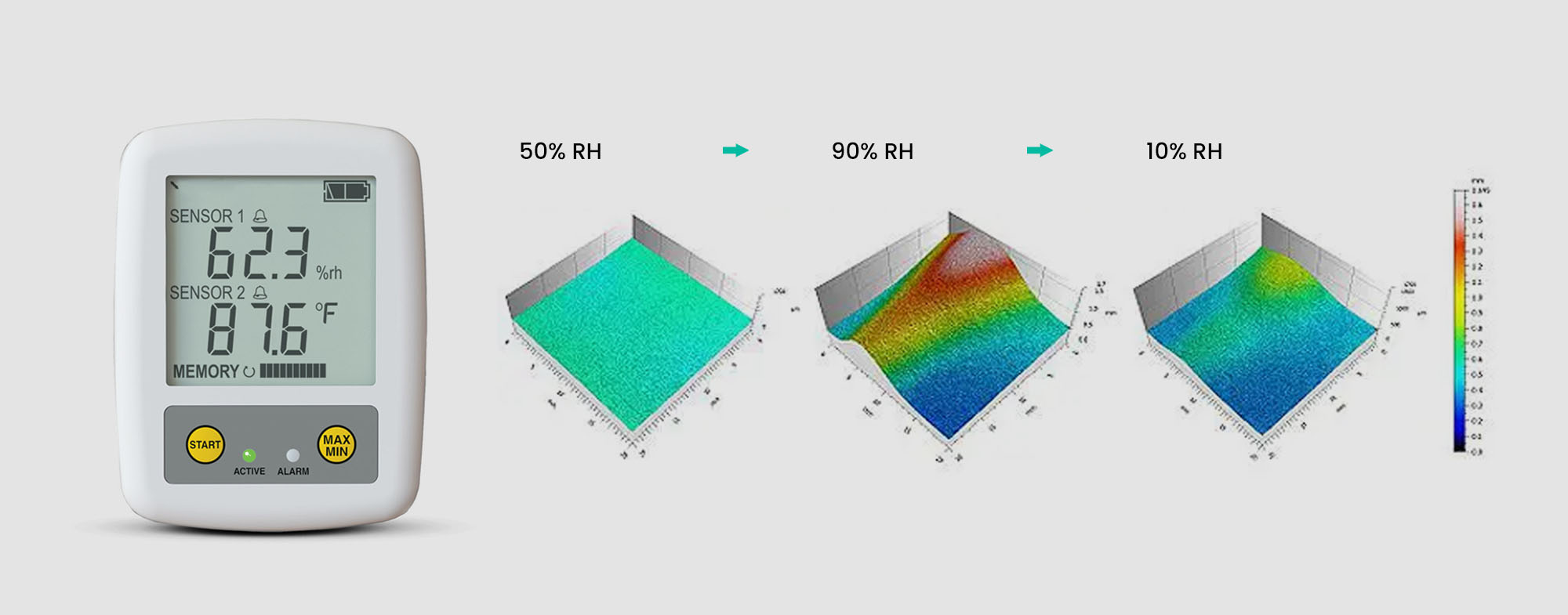

EFFECT OF HUMIDITY ON PAPER

Talking about paper, temperature and humidity majorly affect the same as compared to Film.

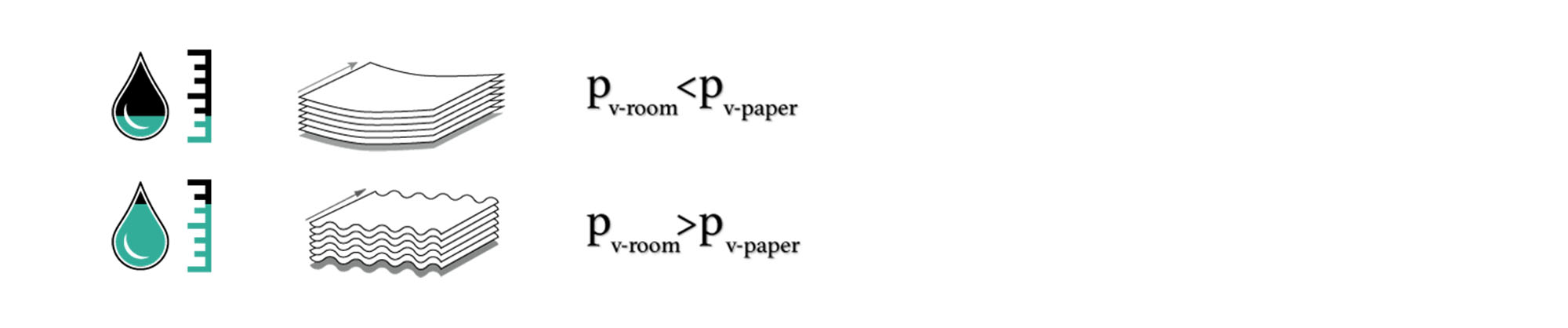

As the humidity increases, the paper will absorb it, ultimately leading to increased Water Percentage in the Paper.

Following that, the paper will become wrinkled and disfigured, which becomes trouble when holding a print registration as excessive water in the paper won’t allow it to absorb ink.

In lower humidity, static electricity [hazardous and leads to fire hazards] builds up, giving rise to debris that affects the printing quality.

CONCLUSION

To conclude, the Temperature and Humidity of the work environment cannot be too high or too low to maintain the print quality. The suggested work temperature would be between 20˚~30˚. The suggested humidity would be between 50%~70%.