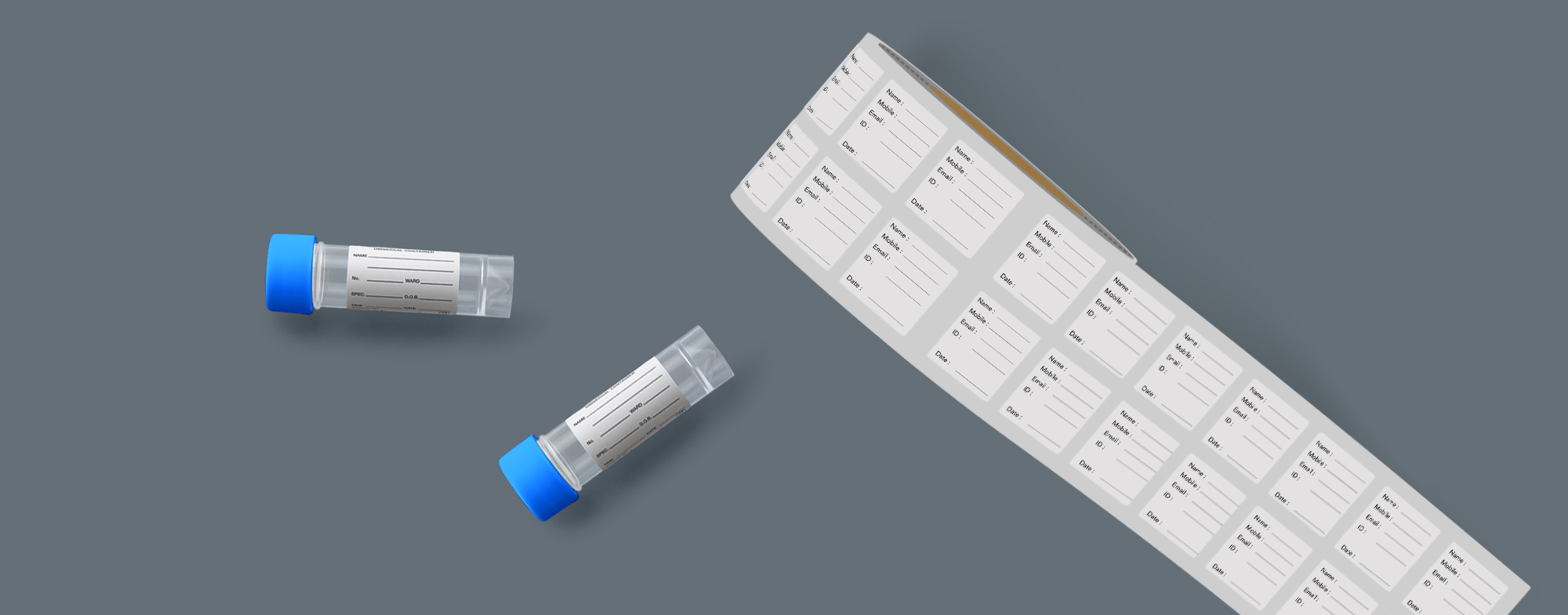

Sterilizable Labels are used for the identification of products and materials that undergo harsh 1DZ sterilization processes. All our Sterilizable Labels are developed, tested, and certified to withstand high temperature and pressure when exposed to processes such as Gamma/E-Beam (Radiation), Ethylene Oxide (EO), Steam Autoclave, Hydrogen Peroxide / Plasma (VH202), Dry Heat and Formaldehyde, etc.

Key Features

In the field of healthcare, maintaining strict hygiene standards is non-negotiable. Sterilization is a critical step in ensuring that medical instruments and equipment are free from harmful microorganisms. Sterilization labels and tapes, often referred to as sterilization indicators, are essential tools that help healthcare professionals confirm that the sterilization process has been successful. In this article, we will delve into the significance of sterilization labels and tapes and how they contribute to medical safety and regulatory compliance.

Sterilization Labels: The Guardians of Medical Safety

Sterilization labels are small yet powerful tools that serve as guardians of medical safety. They provide visible evidence that medical instruments and equipment have undergone the necessary sterilization procedures. The absence of these labels could lead to the use of unsterile items, potentially endangering patients and healthcare providers.

Sterilization Tapes & Labels: Ensuring Compliance

In the highly regulated healthcare industry, compliance with sterilization standards is crucial. Sterilization tapes and labels are designed to meet and exceed industry-specific regulations, giving healthcare facilities peace of mind that they are adhering to the highest safety and quality standards.

Key Functions of Sterilization Labels and Tapes:

Types of Sterilization Labels and Tapes:

Steam Sterilization Labels: These are designed for autoclave sterilization and often change color when exposed to steam sterilization conditions.

Ethylene Oxide Sterilization Labels: Ethylene oxide (EtO) is used for sterilization, and labels for this method indicate exposure.

Reactive Sterilization Tapes: These tapes change color or show specific patterns when the sterilization process is successful.

In conclusion, sterilization labels and tapes are crucial elements in the healthcare industry, safeguarding patient safety and ensuring regulatory compliance. By providing visual confirmation of sterilization, aiding batch traceability, and contributing to the overall quality assurance, they play a vital role in maintaining high standards of hygiene and safety. Healthcare professionals and facilities must invest in reliable sterilization labels and tapes to uphold the integrity and safety of their medical practices. These small labels are a big part of ensuring the highest standards of care.