Label printing is crucial in many industries, including manufacturing, logistics, healthcare, and retail. The accuracy and authenticity of labels are of utmost importance to ensure product quality, traceability, and compliance with regulations. This technical blog will delve into the significance of using certified and genuine label stock materials in label printing.

Label printing is crucial in many industries, including manufacturing, logistics, healthcare, and retail. The accuracy and authenticity of labels are of utmost importance to ensure product quality, traceability, and compliance with regulations. This technical blog will delve into the significance of using certified and genuine label stock materials in label printing.

Section 1: Understanding Label Stock Material

Label stock material refers to the base material on which labels are printed. It is vital in determining label durability, adhesion, and overall quality. To ensure the labels meet industry standards and requirements, it's essential to use certified and genuine label stock materials.

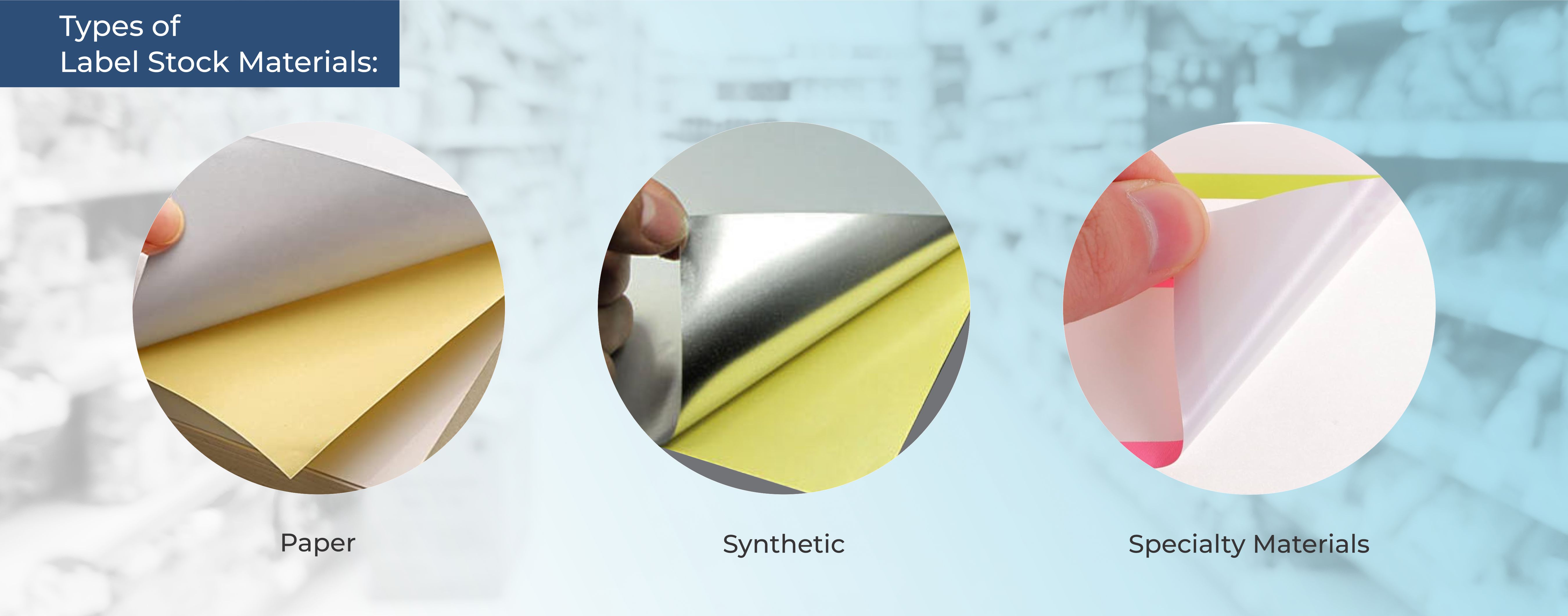

1.1. Types of Label Stock Materials:

1.1. Types of Label Stock Materials:

-

Paper: Commonly used for indoor labels and packaging.

-

Synthetic (Polyester, Polyethylene, Polypropylene): Durable materials for outdoor, waterproof, and chemical-resistant labels.

-

Specialty Materials (Thermal transfer, Direct thermal): Suitable for variable data printing.

Section 2: Benefits of Certified Label Stock Material

Section 2: Benefits of Certified Label Stock Material

2.1. Consistency and Reliability:

-

Certified label stock materials guarantee consistent label quality and performance.

-

Reduced risk of defects or deviations that could compromise labelling accuracy.

2.2. Compliance:

-

Many industries have specific regulations regarding label durability and information accuracy. Using certified materials ensures compliance with these requirements.

2.3. Improved Printability:

-

Certified materials are designed for optimal print quality, reducing issues like smudging, fading, or bleeding ink.

Section 3: Identifying Genuine Label Stock Materials

Section 3: Identifying Genuine Label Stock Materials

3.1. Trusted Suppliers:

-

Sourcing label stock materials from reputable suppliers is essential.

-

Verify the authenticity of materials by checking supplier certifications and credentials.

3.2. Material Specifications:

-

Ensure that the label stock material meets the required specifications for your application.

-

When necessary, check for certifications such as UL, CSA, or FDA approvals.

Section 4: Certification Standards

Section 4: Certification Standards

4.1. UL Certification:

-

Underwriters Laboratories (UL) certification is vital for products that require safety labels.

-

UL ensures that label materials meet strict safety and performance standards.

4.2. CSA Certification:

-

Canadian Standards Association (CSA) certification is essential for products intended for the Canadian market.

-

CSA-certified label materials comply with Canadian safety and quality standards.

4.3. FDA Compliance:

-

Compliance with FDA regulations is critical for labels used in the food, pharmaceutical, or healthcare industries.

-

Ensure that label materials are FDA-approved for safe and accurate information display.

Section 5: Conclusion

In conclusion, label printing with certified and genuine label stock material is essential for ensuring label accuracy, durability, and compliance with industry standards and regulations. Whether you are labeling products, packaging, or assets, using high-quality materials from trusted suppliers will enhance your printing process's efficiency and reliability.

By prioritizing using certified and genuine label stock materials, you create labels that look good and perform well, withstand environmental factors, and meet the necessary safety and regulatory requirements.