In industrial and laboratory settings, labels don’t just need to stick they need to survive. From high-grade solvents to corrosive acids, chemicals can wreak havoc on ordinary labels, leading to smudging, peeling, fading, or complete data loss. That’s why chemical-resistant labels exist—not as a luxury, but as a necessity.

At Monarch Graphics, we engineer labels that thrive in environments where most would fail.

Why Ordinary Labels Don’t Make the Cut

Why Ordinary Labels Don’t Make the Cut

In many industries, exposure to chemicals is part of the daily routine. But regular labels:

- Break down on contact with solvents or oils

- Smear or erase crucial print data

- Curl, peel, or degrade under chemical sprays

- Fail to comply with safety and identification protocols

When labels fail, the risks are real—missed batch recalls, lab safety hazards, and regulatory non-compliance.

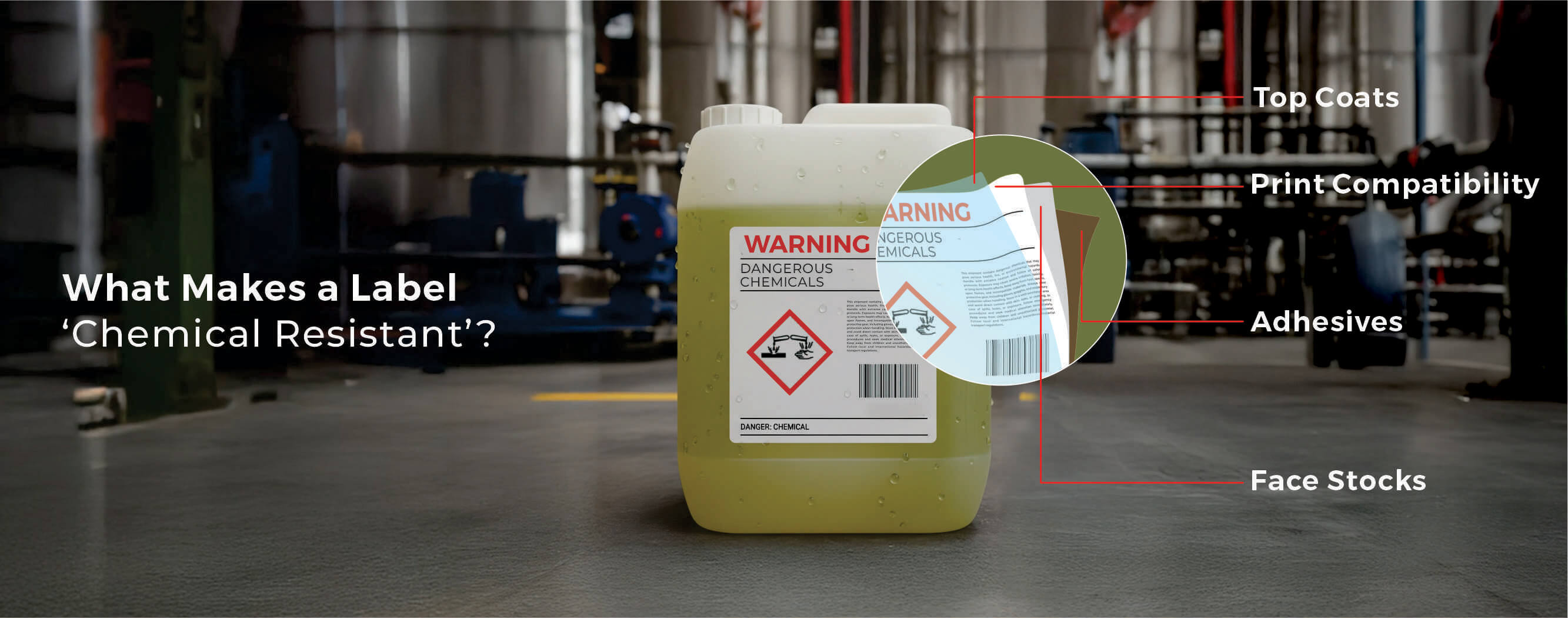

What Makes a Label ‘Chemical Resistant’?

What Makes a Label ‘Chemical Resistant’?

It starts with smart layering and durable materials.

Here’s what sets chemical resistant labels apart:

- Face Stocks: Made of high-performance synthetics like polyester or polypropylene

- Adhesives: Engineered for long-term bonding on glass, plastic, metal, or textured surfaces even when wet

- Top Coats: Special coatings prevent smudging and protect printed text from solvents and abrasion

- Print Compatibility: Designed for thermal transfer or laser printing to ensure permanent readability

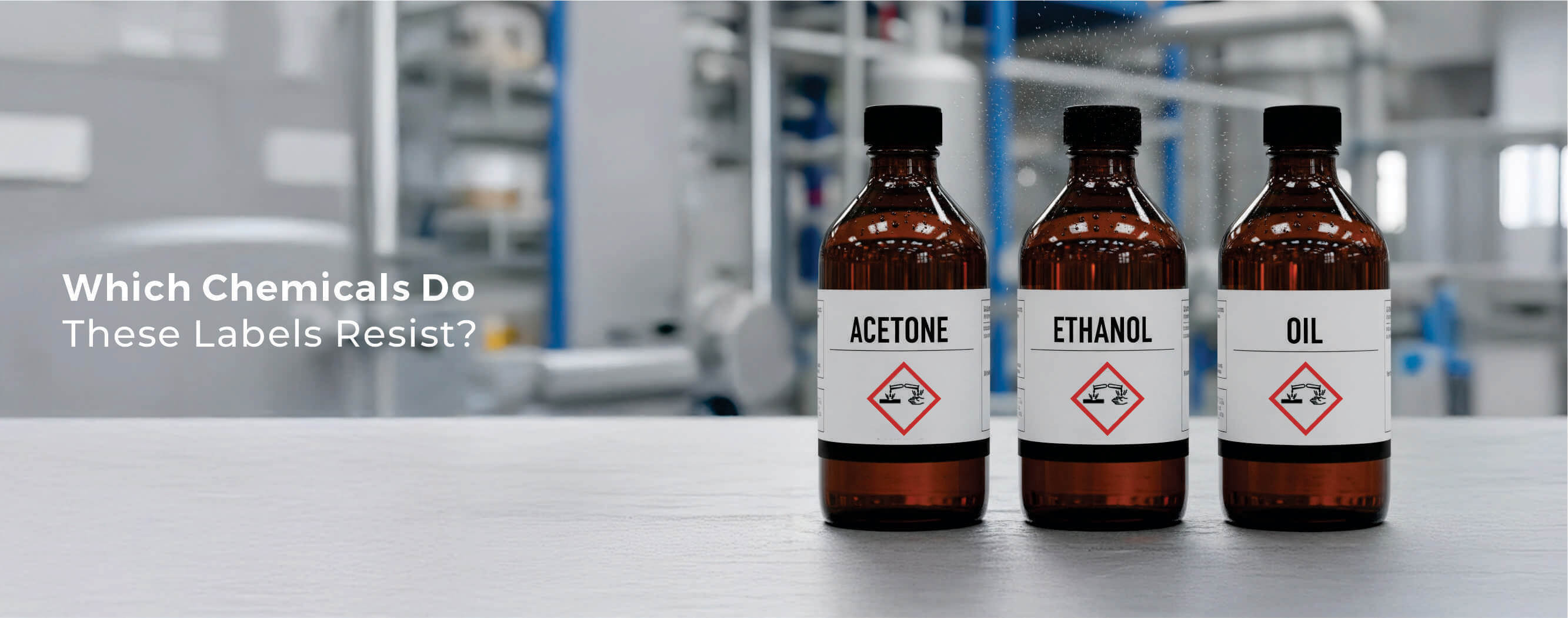

Which Chemicals Do These Labels Resist?

Which Chemicals Do These Labels Resist?

Monarch’s chemical-resistant labels are tested against:

- Ethanol, isopropanol, methanol

- Acetone, MEK (methyl ethyl ketone)

- Sodium hypochlorite, hydrogen peroxide

- Lubricants, oils, coolants, and detergents

Industries That Rely on Chemical Resistant Labels

Industries That Rely on Chemical Resistant Labels

Here’s where these labels are indispensable:

1. Pharmaceutical & Biotech Labs

Used for sample tubes, reagent bottles, and test trays exposed to alcohol-based disinfectants or sterilants.

2. Chemical Manufacturing

Drums, containers, and pipes carrying hazardous substances require permanent labeling that won’t dissolve or smudge.

3. Automotive & Engineering

Labels for engine parts, fluid containers, and under-the-hood components must survive grease, oil, and brake fluids.

4. Petrochemical & Oil & Gas

Valves, barrels, and toolkits labeled for inventory, maintenance logs, or safety warnings often in direct contact with harsh chemicals.

5. Industrial Cleaning & Sanitation

Cleaning equipment, PPE kits, and chemical containers must retain readable ID labels even after multiple wipe-downs and splashes.

Real-Life Applications

Real-Life Applications

- Lab sample vial labels that endure sterilization sprays

- Hazmat drum labels stored outdoors, exposed to rain and solvents

- Automotive barcode labels used for traceability during assembly and post-sale servicing

- Floor cleaning machines labeled with usage and safety instructions that face continuous contact with detergents

- Maintenance tags in oil rigs or factories that need to survive aggressive chemical cleaning cycles

Built for Safety & Compliance

Built for Safety & Compliance

Many sectors must adhere to strict labeling standards:

- GHS-compliant labels for hazardous material classification

- BS5609 for chemical drum labels used in marine transport

- FDA/OSHA label durability standards in labs and manufacturing

Monarch’s chemical-resistant labels are built to meet these compliance norms ensuring durability, legibility, and safety under pressure.

Why Choose Monarch Graphics?

Why Choose Monarch Graphics?

We don’t just print labels—we engineer labeling systems for your environment.

- Materials tested in real-world industrial and lab conditions

- Custom shapes, formats, and adhesives for any container

- Thermal-transfer and laser-printable solutions

- Resistant to heat, moisture, abrasion, and chemicals

- In-house R&D for special compliance requirements

Conclusion

Your labels face more than wear and tear—they face chemical warfare.

Whether it’s acetone in a lab, diesel on an engine, or solvents in a plant, Monarch’s chemical-resistant labels don’t quit.

Label the tough stuff—with labels made tougher.

Explore our range: www.monarchgraphics.in