Shipping hazardous goods via sea is a complex, heavily regulated process that requires extreme attention to detail. Whether it's chemical drums, industrial solvents, or pharmaceutical waste, the labeling of such products must withstand harsh maritime conditions, including saltwater exposure, chemical spills, and rough handling.

Shipping hazardous goods via sea is a complex, heavily regulated process that requires extreme attention to detail. Whether it's chemical drums, industrial solvents, or pharmaceutical waste, the labeling of such products must withstand harsh maritime conditions, including saltwater exposure, chemical spills, and rough handling.

This is where BS5609-certified labels come into play. Developed under the British Standard BS5609, these labels ensure that critical hazard information remains intact, even in the most extreme conditions. Failure to comply with BS5609 labeling regulations can lead to shipment rejection, legal penalties, and significant financial losses.

So, what exactly is BS5609 certification, and why is it non-negotiable for businesses shipping hazardous materials by sea? Let’s break it down.

What Is a BS5609 Label?

BS5609 is a maritime durability certification for pressure-sensitive labels used in shipping hazardous goods. It is a mandatory requirement for chemical labels that must comply with the International Maritime Dangerous Goods (IMDG) Code and the Globally Harmonized System (GHS).

This certification is divided into two key sections:

- Section 1: Base Material Testing

- Evaluates label material durability when exposed to saltwater, UV radiation, and physical abrasion.

- The label must remain attached and not degrade after a 3-month immersion test in seawater.

- Section 2: Printed Label Performance

- Tests adhesion strength, ink durability, and resistance to mechanical abrasion.

- Ensures that printed information, including hazard warnings, remains fully legible even after exposure to harsh environments.

Why BS5609 Labels Matter in Maritime Shipping

-

Regulatory Compliance – BS5609 labels ensure that shipments meet United Nations (UN) GHS, the European CLP (Classification, Labeling, and Packaging) regulation, and the International Maritime Organization (IMO) standards.

-

Resistant to Extreme Conditions – Unlike ordinary labels, BS5609-certified labels do not fade, peel, or disintegrate when exposed to saltwater, strong chemicals, or direct sunlight.

-

Prevents Shipment Delays and Rejections – Without compliant labels, shipments can be held at customs, leading to significant financial losses.

-

Enhances Safety in Emergencies – In case of spills or accidents, emergency responders rely on clear and legible labels to take immediate action.

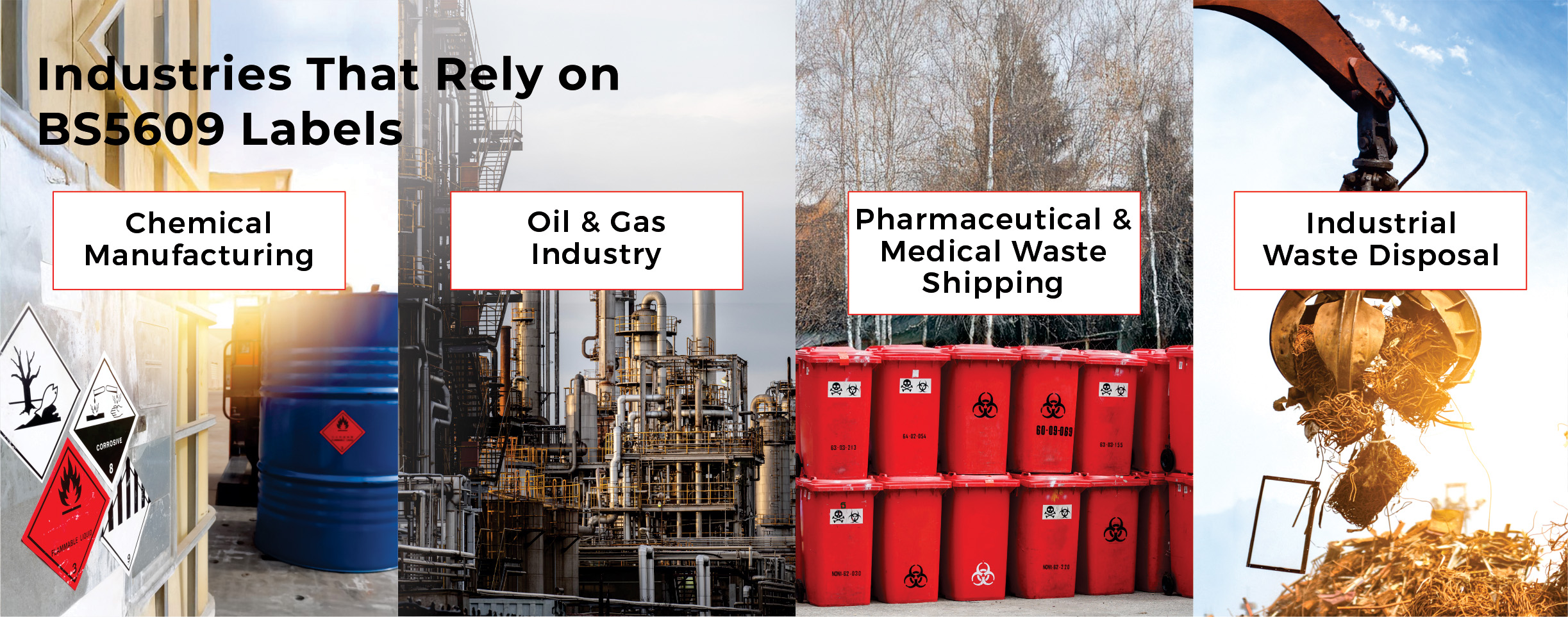

Industries That Rely on BS5609 Labels

-

Chemical Manufacturing – Ensuring safe transport of flammable, corrosive, and toxic substances.

-

Oil & Gas Industry – Labeling of petroleum products, industrial lubricants, and fuel containers.

-

Pharmaceutical & Medical Waste Shipping – Preventing contamination during biohazardous material transport.

-

Industrial Waste Disposal – Assuring proper identification of hazardous waste shipped for treatment or disposal.

Choosing the Right BS5609 Label

Businesses must partner with reliable label converters to ensure compliance. Monarch Graphics specializes in durable, tested BS5609-certified labels designed for extreme maritime conditions. Choosing the right label material, ink, and adhesive formulation is key to avoiding non-compliance penalties and ensuring cargo safety.

Conclusion

BS5609 labels are not just compliance requirements—they are an essential part of safe, efficient, and legally sound shipping operations. Companies that invest in high-quality, tested labels will benefit from fewer delays, reduced risks, and enhanced brand reputation.